| PRP | ESP | |

|---|---|---|

| POWER kVA | 20 | 22 |

| POWER kW | 16.2 | 17.8 |

| Voltage | Frequency | Phase | Alternator |

|---|---|---|---|

| 400 | 50 | Three Phase | TAL-A40-F |

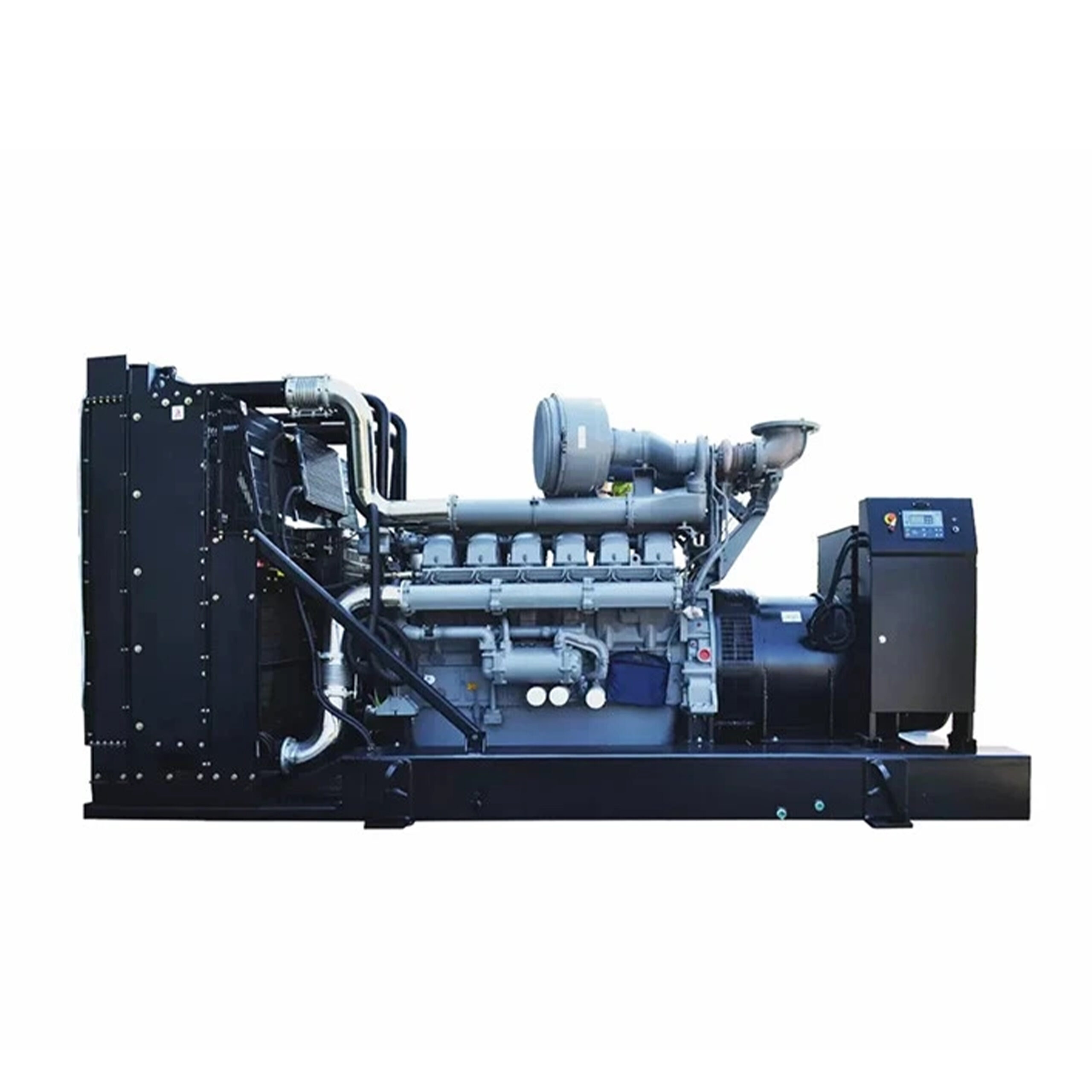

PERKINS is a well-known brand in the diesel engine industry, recognized for its high-quality, reliable engines that are used in a variety of applications, including agriculture, construction, and power generation. Founded in 1932, Perkins has built a strong reputation for innovation and performance.

Durability: Perkins engines are designed to withstand harsh operating conditions, making them suitable for demanding environments.

Efficiency: Their engines often focus on fuel efficiency and low emissions, aligning with modern environmental standards.

Versatility: Perkins offers engines in various power ranges, allowing them to be used in multiple applications, from small machinery to large industrial equipment.

Support and Service: The brand provides extensive support and service options, ensuring that customers have access to parts and technical assistance when needed.

Global Presence: With manufacturing facilities and service networks around the world, Perkins ensures that its engines are readily available and supported in many markets.

Perkins diesel engines are a popular choice for those seeking reliable power solutions across different industries.

| Equipment Specification | |

|---|---|

| Voltage | 400 V |

| Frequency | 50 Hz |

| Prime Power | 16.2 kW |

| Standby Power | 17.8 kW |

| Factor | COS=0.8(Lag) |

| Engine | |

| Engine Specifications | 1500 rpm |

| Rated Engine Output | 20.6 kW |

| Manufacturer | Perkins |

| Model | 404D-22G L |

| Engine Type | 4-stroke diesel |

| Injection Type | Indirect |

| Aspiration Type | Natural |

| Displacement | 2.2 L |

| Cooling System | Liquid |

| Alternator | |

| Generator | Leroy Somer |

| Model | TAL-A40-F |

| Poles | 4 |

| Insulation | H class |

| Enclosure | IP23 |

| Exciter system | Self-excited, brushless |

| Voltage regulator | A.V.R. (Electronic) |

| Coating type | Standard |

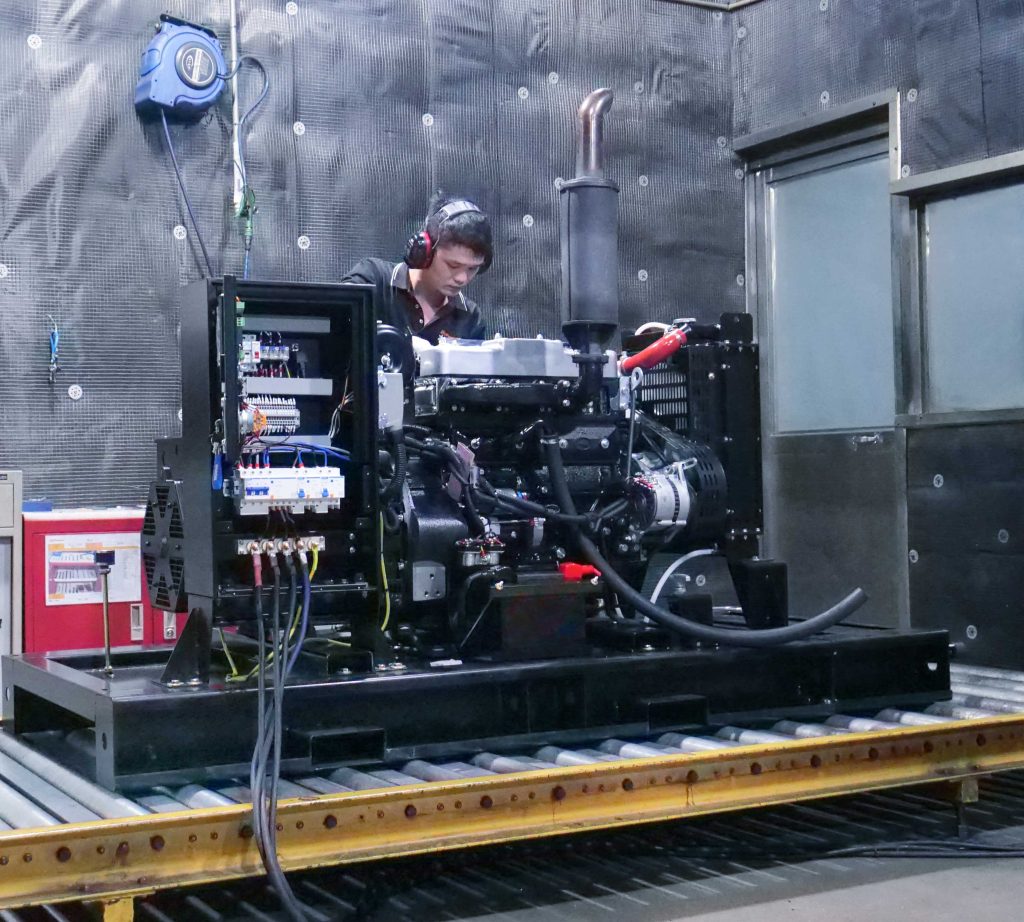

Quality Inspection Team

In our factory, excellent quality comes not only from strict management, but also relies on advanced quality inspection equipment. We have introduced leading testing instruments to ensure that every product is strictly inspected.

Quality Inspection Process

From the moment raw materials arrive, we rigorously control quality. Throughout the production process, we establish multiple critical quality control points and rigorously monitor every step to ensure precise and accurate workmanship. Before shipping, the final product undergoes comprehensive performance and appearance testing.

Yes, we offer OEM services. Our team of engineers can design and produce products tailored to your specific requirements.

Yes, our products hold multiple invention patents and are fully certified with CE, ISO9001 standards and EU Stage V emission standard.

We offer comprehensive after-sales support, including technical consultations, installation guidance, and repair services. If you encounter any issues, feel free to contact us.

For standard products, delivery typically takes 15-30 days. For custom orders, the lead time will be confirmed based on specific requirements.

We strictly adhere to ISO9001 standards in our production process, and every product undergoes rigorous testing before leaving the factory to ensure performance and reliability.